Valleyfair is located right across the street from KEB America. We get daily reminders of the fun and thrills that amusement parks offer. The next time that you see a roller coaster or an amusement park ride, take some time to notice all the industrial automation equipment used: spring applied brakes, servo motors, HMIs, safety relays, etc.

This post outlines some of the considerations for designing automation for amusement rides and how KEB products can be used.

Safety

Thrill-seekers go to amusement parks for a rush. This means fast accelerations, sudden drops, and being inverted. Part of the thrill comes from the perception that the ride is pushing the boundaries of being unsafe. Of course, the rides must be extremely safe – this goal is first and foremost.

Amusement rides are often designed to an industrial safety norm like ISO 13849. In ISO 13849, there is a process for assessing all risk possibilities. Then a suitable safety level must be decided along with a design that mitigates the risk. In general, amusement park rides will be designed to a SIL3/PLe level. This safety level often includes redundant components and a means to detect abnormal or unsafe conditions.

Failsafe Brakes

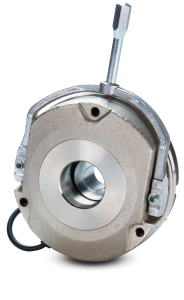

KEB is probably best known in the entertainment industry for our spring-set brakes. KEB failsafe spring-set brakes provide brake engagement when power is removed. The brake is often set when an e-stop circuit is closed or the load should be stopped and held as quickly as possible.

KEB brakes use a redundant spring design where each spring is rated for over 10 million cycles. Brakes are often equipped with a manual hand release (for maintenance) and a microswitch whose signal can be fed back to central control. If the brakes are located outside in the elements, KEB can offer IP65 versions.

Gearmotors

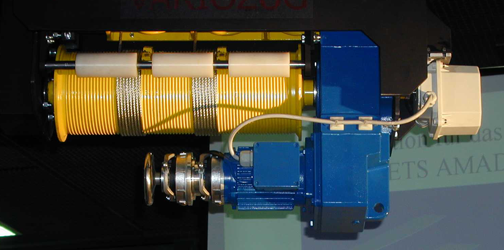

Oftentimes, machines require two separate and independent brakes. One brake is commonly fitted to the motor. KEB also supplies integral gearmotors that use our own spring-set brake technology. Our gearmotors can be found on demanding equipment including moving platforms and winches.

KEB offers both induction and AC PM servo motors and the motors can be fitted with a SIL-rated safety encoder. Increasingly, servo motors are being used in rides. Servo motors are more compact than induction motors which are advantageous when the machine has limited space. One word of caution – many servo motor manufacturers do not use a spring-set style brake capable of multiple e-stops. This is one example where KEB has a better mousetrap – our TA servo motor line can be equipped with a true spring-set brake.

Drives

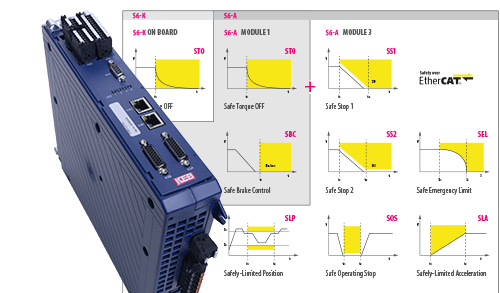

SIL3 rated functionality has been available in VFDs for some time now – specifically, Safe-Torque-Off (STO). All of KEB’s new generation drives include STO as standard. STO provides two independent means to disable the output IGBTs. If the drive does not receive both STO inputs, then the drive will not output current and a rotating magnetic field to the motor.

But STO might not be appropriate for some applications (e.g. hoisting) where you do not necessarily want to cut all power to the motor in an e-stop. Have no fear. KEB’s Safety Module 3 includes many different IEC61800 functions that can be activated at the drive level. These functions can be activated in the case of overtravel, overspeed, and e-stop events. Typical Safe Drive functions include Safe Limited Speed (SPS), Safe Limited Direction (SLD), and Safe Limited Position (SLP).

Another option with KEB’s Safety Module 3 is the ability to use Failsafe over EtherCAT (FSoE). FSoE allows the safety functionality to be communicated over a standard network cable. FSoE features a number of features (e.g. checksums, watchdog timers) that ensure the safety information is properly being sent and received. Read this article for more information on FSoE and its benefits.

It should be noted that all of KEB’s Safe Drive functions conform to a SIL3 level and are independently certified by TUV Rheinland.

Safety PLC and IO

KEB also offers SIL3 rated safety PLC and IOs that typically run in parallel to the main machine control. The Safety PLC monitors all the critical switches, positions, etc. In the event of an emergency, the Safety PLC should quickly and reliably react.

KEB’s Safety PLC and IO also operate with FSoE which allows them to be connected with a standard network cable.

HMI

Finally, the HMI provides an operator with a useful dashboard for operating the machine and displaying diagnostics and fault codes. While the HMI itself does not carry a safety certification, it can be designed in a way that helps promote safety. Uncluttered screens that allow for clear machine operation and reading of diagnostics. Other functions integrated into KEB’s HMI product like password user management and alarm logging are useful.

Industrial components designed for long life cycles

Amusement rides are intended to provide years and years of service. So it is important that components are selected that will be supported and available for many years in the future. Sometimes, commercial-grade components seem attractive with good performance specs at low price points. However, many of these components have a supported lifetime that is very short – a couple of years, maybe even a couple of months. When using these components, it’s possible that the system will need to be re-engineered or upgraded very soon to accommodate obsolete parts.

KEB takes a lot of consideration to design our industrial products using components that have a long guaranteed support and manufacturing life. For example, KEB selects chipsets that are guaranteed to be offered support for an extended lifetime. Some manufacturers achieve low costs by using obsolete or end-of-life chips. If you’ve been burned and had to redesign a newly released control system, you won’t make the same mistake twice.

But hardware is not the only thing affected by product lifecycles. Operating systems also need support to ensure stability and security. Again, KEB chooses operating systems (e.g. Windows Embedded) that are guaranteed a long lifetime of support.

Price is important but don’t let it be the only factor to consider. Future availability and support should be important – your future self with thank you.

Remote Access

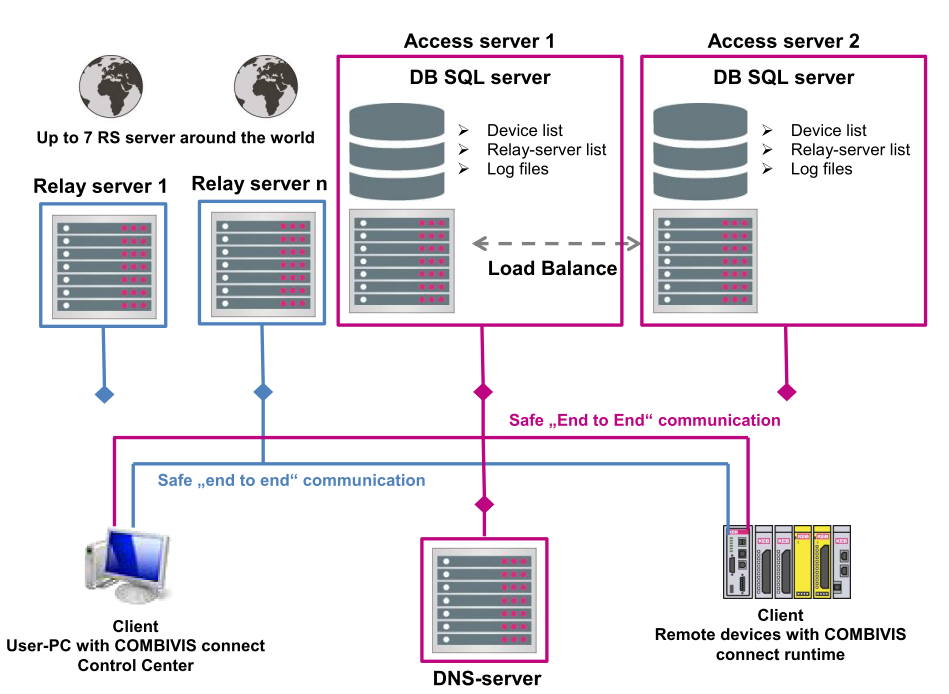

Increasingly, OEMs of amusement rides are demanding a way to get remote access to their equipment. The remote access can be used for troubleshooting, updating functionality, and gathering usage statistics.

Obviously, security is a concern which is why KEB’s C6 Router is a good choice. KEB’s VPN Router offers extensive security features. This includes the ability to manage firewalls, users, and groups through the COMBIVIS Connect software. The Router also has hardware features like an input that must be activated through a key switch before the Router can transmit. Additionally, an output is available for confirmation back to the PLC that the Router is in transmit mode.

The Router comes in a few different flavors but most users will want the Cellular version. This allows remote access to the equipment without running Ethernet cables or managing local WiFi connections.

Have fun next time you go on a ride and notice all the automation that makes it happen.

Get in touch with a KEB engineer if you’d like to know more about any of our products.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.