An interesting application that uses nearly all KEB Automation products is an Antenna control system. KEB is best suited for difficult and demanding applications and this one is no different.

First, the antenna application demands high motion control performance. Antennas are used to track satellites and require precise and dynamic positioning capability. This puts demands on both the control and mechanical system. The mechanical system must provide low backlash and be able to withstand high peak forces in the case of wind gusts.

The second reason this is a difficult application is because of the extreme environments the Antennas are commonly installed in. They can go into remote areas like mountaintops (high elevation), deserts (high ambient temps), jungles (condensation), etc. This puts a demand on the mechanical parts that they can withstand wide temperature extremes, condensation, etc.

Related Article: Mastering the Challenges of using VFDs at High Altitudes

KEB always seeks to offer the best technical and commercial solution for the application. This differentiates us and means we can potentially offer a customized solution for the application. This is particularly true for our mechanical and motor options. This post highlights solutions we have offered for the Antenna industry and what is possible in the KEB product portfolio – if you have questions or want to discuss with an application engineer, contact us or read on.

Controls

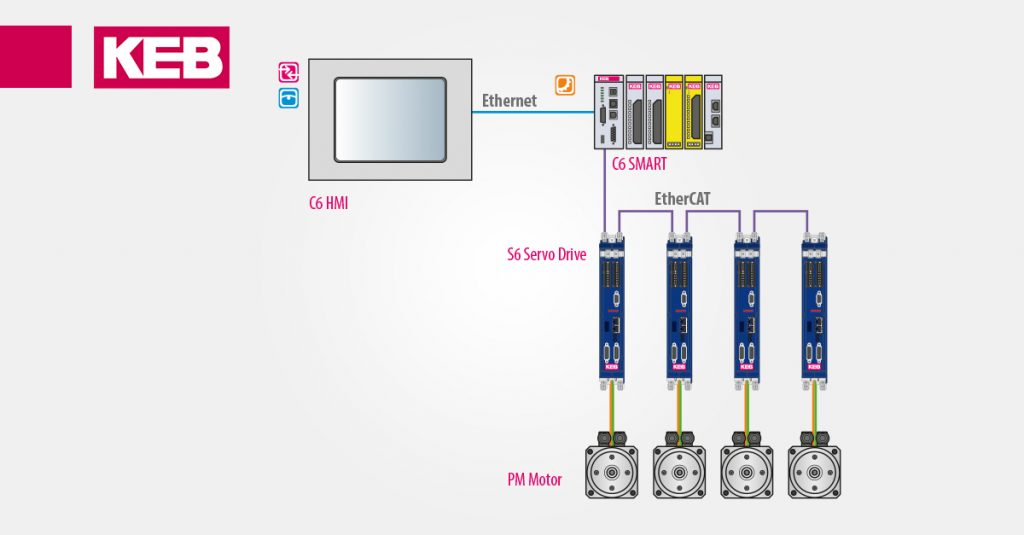

Ultimately, the antennas need to accurately track position in real-time so KEB’s EtherCAT master controllers are perfectly suited. First, EtherCAT as an industrial protocol is perfect since it offers excellent deterministic performance for motion control applications.

KEB’s SMART EtherCAT master is capable of handling multiple axis of coordinated motion control

KEB offers a range of control products depending on desired cycle times and axes count. Everything from an embedded controller that would handle 4 axes of coordinated motion to a full Industrial PC that would be capable of 30+ axes of coordinated motion.

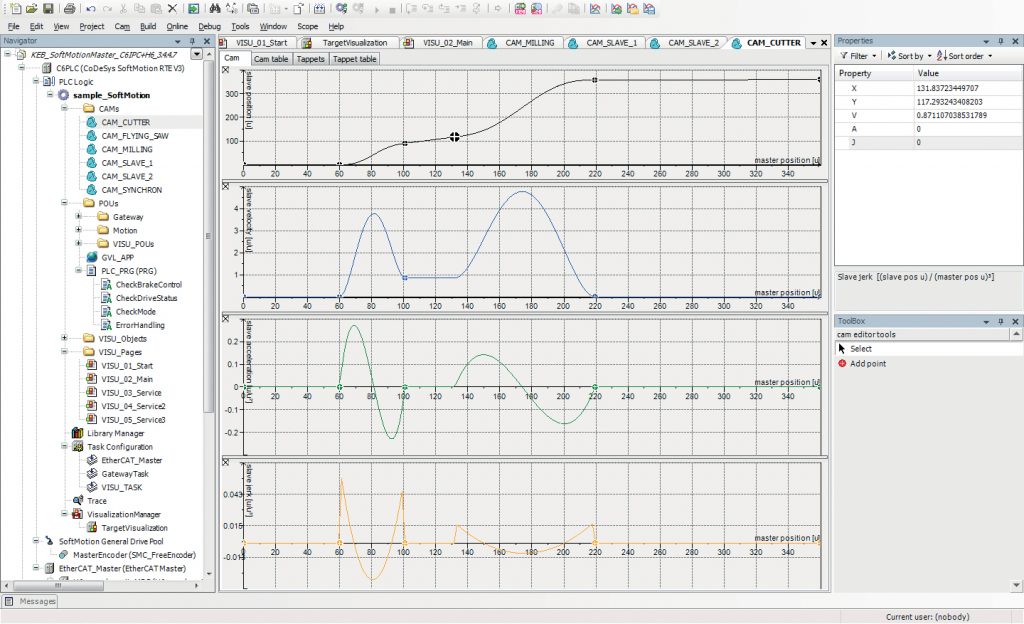

KEB controls program in Combivis Studio environment which supports all IEC 61131-3 languages including Structured Text (ST) and Ladder Diagram (LD). Included in the Combivis programming environment are KEB libraries. These pre-engineered, tested function blocks facilitate functionality like EtherCAT drive communication, master-slave synchronization for multiple axes, and custom Cam profiles. Ultimately, this saves the design or control engineer significant time and money.

Additionally, a machine program is easily scaled across different KEB control hardware. This means a customer can easily re-use code while upgrading processing power (e.g. large antenna array).

KEB supports secure remote connections using our Connect platform. Remote applications will benefit from our GSM cellular option so controls could be updated in the field as needed.

I/O

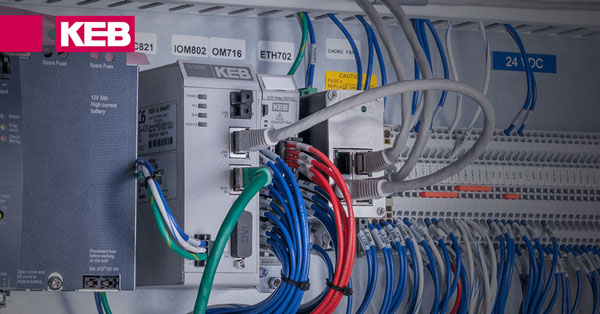

KEB offers a number of different EtherCAT I/O blocks that can be easily added to the control system. These include digital and analog inputs and outputs. Pulse counters. Temperature sensor modules. Also, EtherCAT extender modules make it very easy to connect remote I/O boxes with a CAT5 network cable.

Drives

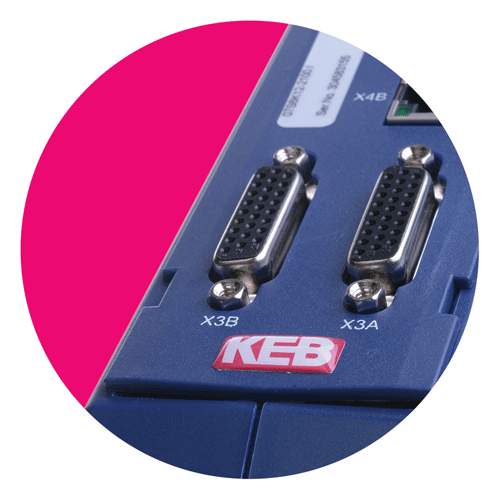

Again, KEB offers different EtherCAT drive options depending on the needs of the application. Most servo motor applications can be solved with the S6 servo drive which includes safe-torque-off, built-in EtherCAT, and a dual-channel encoder input.

If the antenna is large and has multiple axes, the customer might benefit from the H6 which is a shared-bus Multi-axis platform. All other applications including large power (up to 1000Hp) can be solved with KEB’s F6-K EtherCAT drive.

This EtherCAT drive platform also supports 230V applications up to 180 Amps nominal output.

Benefits for the above drives include:

- Fast, native EtherCAT communication.

- CiA402 Motion Control profiles (Homing, Velocity, Torque, etc.)

- Dual Encoder channels

- Support for multi-turn Absolute Encoders (BiSS, Hiperface, EnDAT), resolvers, TTL/HTL encoders

A number of different positioning schemes are possible. A simple amplifier topology is possible where the drive follows an external motion controller’s 0-10V analog velocity command. Alternatively, the position loop for single-axis applications could be closed in the drive using the drive’s 32-bit Internal Positioning Module (IPM). Having the drive handle the position simplifies the main controller as the controller only needs to provide target positions as needed. Finally, if the control is connected to the drive with EtherCAT, the positioning can be handled with KEB’s CiA 402 motion control profiles.

Another interesting option is for the KEB drive to run in torque control or to provide a torque bias on the gearing. In this way, the drive can remove any backlash in the gearing and drivetrain.

Servo Motors

This is where things get fun. Most off-the-shelf servo motors are not ideal for an outdoor antenna application.

KEB can provide special motors with unique features that competitors do not offer. Here are some highlights:

- Up to P3 paint protection (EN ISO 12944) for moist, humid environments.

- Drain or Breathing plug – For applications prone to condensation

- Holding brake – Oftentimes, there is a need to “park” the antenna in a “birdbath” position when the axes are disabled. KEB offers brake options that include a manual hand release and a microswitch that provides engagement feedback.

- Encoders – KEB offers a wide range of encoders including absolute types like BiSS, Hiperface, and EnDat.

- Large servo motors – Many companies provide small servo motors. Fewer companies provide large servos. KEB has a full range of servos rated for S1 continuous duty – contact us for details on what is possible.

- Connectors – KEB can offer special MIL connectors for feedback and power if desired. Also, rotatable or straight options are possible.

- Hand Wheel / Hand Crank – Under the loss of power, sometimes it is required to manually move the drivetrain into position. This can be done by supplying an extended shaft on the motor NDE. KEB can also supply a cover for this shaft with a sensor that indicates when the cover has been removed.

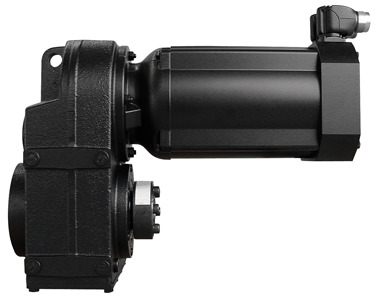

Gearing

Gearing is typically used to provide a slow, high torque output. KEB has several different gearing options. An excellent combination of performance and cost is to use KEB’s low backlash version of our helical gearing. The gearing is available in inline and right-angle configurations. Depending on the ratio, the backlash of these precision gears can match the performance of more expensive planetary gearing.

Again, special paint and seals are available to combat tough environments.

Brakes

At least one, possibly two, holding brakes are needed to lock the antenna. This is typically needed during high wind or abnormal situations. The brakes are usually going to be power-off or spring-set designs. KEB offers a number of different models and options but here are some of the common requirements:

- Up to IP67 – Watertight

- Microswitch – For brake engagement feedback

- Manual hand release – For the manual release of the brake

- Nickel-plated shaft/parts – For corrosive protection

- Special paint – For corrosive protection

- Space Heater – To reduce condensation in the brake parts

Conclusion

Antenna applications requiring positioning and motion control are a perfect fit for KEB. Actually, we have been helping to solve these challenges for many years. Contact us for your next project and see how we can partner.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.