5 Factors to Consider When Choosing a Drive Controller for Highly Automated Machines

When choosing a drive controller for a highly automated, safety-oriented process plant and machines, a number of factors should be considered, including functional safety, real-time communications, ease of integration, feedback control, and stability of the operating environment.

Minimizing production downtime is critical, as well as ensuring the safety and energy efficiency of machines and processes.

In applications such as material handling, textiles, woodworking, plastics, food and beverage processing, packaging, robotics and machine tools, processes are typically high speed with a production plant, equipment and machines operating at high speeds, high reliability, and in a stable operating environment. Minimizing production downtime is critical, as well as ensuring the safety and energy efficiency of machines and processes.

When selecting drive controllers for high-speed, highly automated, safety-oriented applications, a number of important factors should be considered.

#1 – Functional Safety

Machine and process safety is a major consideration when choosing a drive controller for your system. If you are designing a new production process or machine, it is important to consider the cost of safety. For example, could you purchase drive controllers with integrated functional safety? If so, this is likely to reduce the cost of installing separate protective devices, as well as their associated cabling and installation costs.

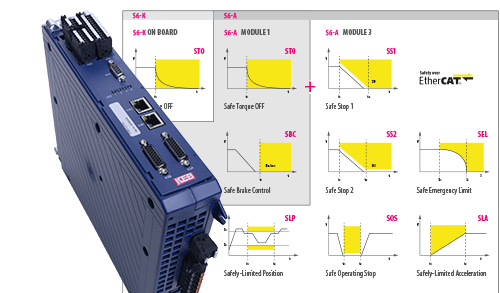

With drive-based safety, the safety functions are shifted into the drive platform. Some suppliers only provide drives with basic safety functions such as STO (Safe Torque Off). Other suppliers go much further providing modular, scalable functional safety from the basic STO to a higher-level encoder-based safety function such as Safe Limited Speed, Safe Maximum Speed, Safe Speed Range, Safe Operating Stop, Safe Direction and Safe Emergency Limit. It is also extremely helpful and cost-effective if the supplier provides its own software that enables faster parameter set up, configuration, analysis and parameterization of key safety indicators and functions.

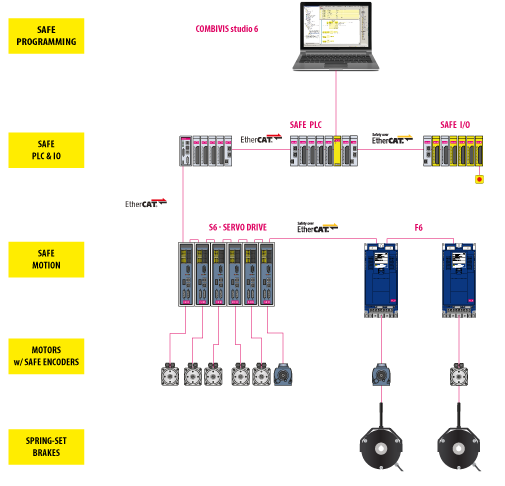

In safety-oriented drive applications, it is important to adhere to the relevant safety standards. Some key questions may need to be asked here, including whether the safety functions of the drive can be used up to IEC 62061-SIL3 levels in accordance with IEC 61508? Or if the functional safety is controlled via FSoE (Fail Safe over EtherCAT)? FSoE will help to ensure the interaction of the drive controllers with safety PLCs and safety I/Os. It may be possible to download encrypted data packets through machine controllers.

FSoE allows all available safety functions to be controlled and secure measurement values (speed, position, etc.) and the switching state of the secure I/Os to be transmitted serially to the safety PLC. Limit values of all safety functions relevant to machine safety can be adapted to the application at any time via FSoE. The result is tremendous flexibility and a significant saving in controls and wiring.

#2 – Real-Time Communications

If machines or production processes are high speed, choosing a drive controller that provides real-time Ethernet-based communications interfaces is critical. These Ethernet-based interfaces typically include ETHERCAT, VARAN, PROFINET, POWERLINK and Ethernet/IP, allowing optimal motor control and communication with higher-level controllers. It is important that these real-time Ethernet-based interfaces are built-in (i.e. fully integrated) to the drives and not simply provided as an add-on module, as these add-ons can create unwanted latency in networks. It is also worth checking whether other diagnostic and/or display interfaces are provided as standard with the drive, such as RS 232, RS 485 and CAN interfaces.

What motor types will the drive need to control? Does the drive support specific motor types, just some, or all major technologies? Motors are available in a wide variety of designs, including synchronous, asynchronous, permanent magnet, synchronous reluctance, linear, high-torque, and high-speed motors. It is therefore important to consider which motor types your drive will need to support, including possible future requirements too. Some drives even provide built-in motor temperature monitoring and integrated brake transistor and brake control.

#3 – Ease of Integration

How easily the drive controllers are able to integrate with other control systems is also important. Part of this is ensuring that the drives provide the necessary real-time Ethernet-based communications interfaces. But it also means checking whether the supplier can provide a wide range of supporting control and automation products such as integrated HMIs, set up, analysis and configuration software, as well as drives accessories to ensure a stable operating environment for the drives, including EMC filters, harmonic filters, output chokes and high-performance ferrite cores (see point 5 below.

The number of software packages should be kept to a minimum in order to minimize the cost of user software licenses, so look for a supplier that offers a comprehensive all-in-one software package for drives set up, configuration, functional safety and applications development, without ongoing/annual licenses or initial set up costs.

#4 – Feedback Control

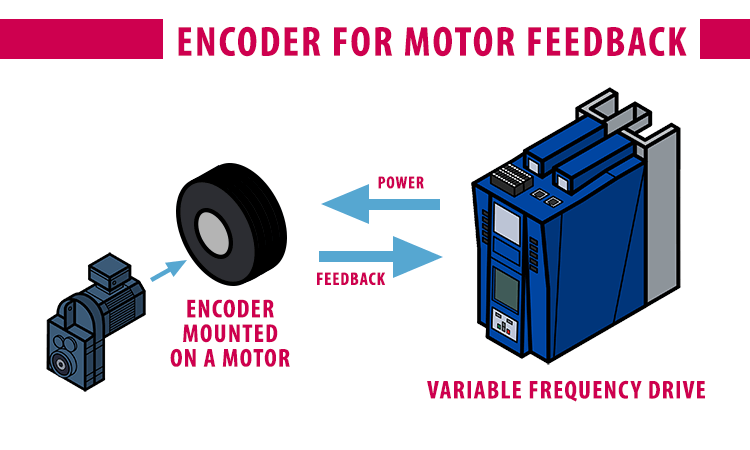

In addition, you may need to consider whether the drive needs to support encoder feedback. Some suppliers now offer drives with two-channel multi-encoder interfaces that allow control of all encoder types such as Resolver, TTL, HTL, SinCos, SSi, EnDAT, Hiperface and BiSS.

#5 – Stable Operating Environment

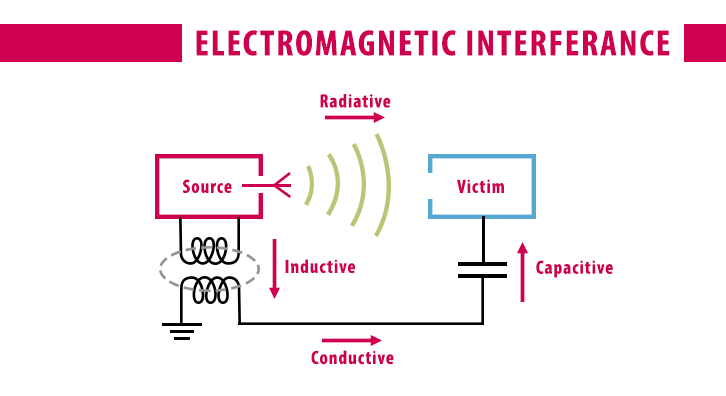

In many industrial environments, ensuring the stability of drive controllers is sometimes overlooked. However, an EMC-compliant assembly with an efficient control cabinet and suppression system is the basis for the safe operation of machines and equipment. When choosing a drive controller platform, it is prudent to check what range of accessories the drives supplier can offer. While these accessories can be sourced from a Third Party supplier, it is better to deal with a single supplier that can provide everything, optimized to suit their own specific drives.

Considering Drive Accessories

Check whether you require any of the following drives accessories:

Mains EMC filters – these reduce the cable-fed emission to the required limits of IEC 61800-3-C1/C2. Other variants may offer low leakage currents or the operation of special mains networks.

Mains chokes – reduce the input peak current draw and the mains distortion. By smoothing the input current draw, the lifetime of the drive is enhanced, particularly at constant high utilization.

Output chokes and filters – these reduce the voltage and current stress of the motor winding.

Combi-filters (EMC/ Output choke) – these space-saving combinations consistently adapt and optimize the drive controller.

Sine-wave filters – protect the motor winding from voltage peaks and allow the use of long motor cables.

Harmonic filters – reduce the low-frequency mains distortion on rectifier-supplied devices. These harmonic filters allow easy integration to a switchgear layout.

Sine-wave EMC filters – allow operation of motors with long motor cables even without screening.

High-performance ferrite cores – these reduce the values of du/dt’s also in the frequency range of the bearing currents.

Let's Work Together

Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.